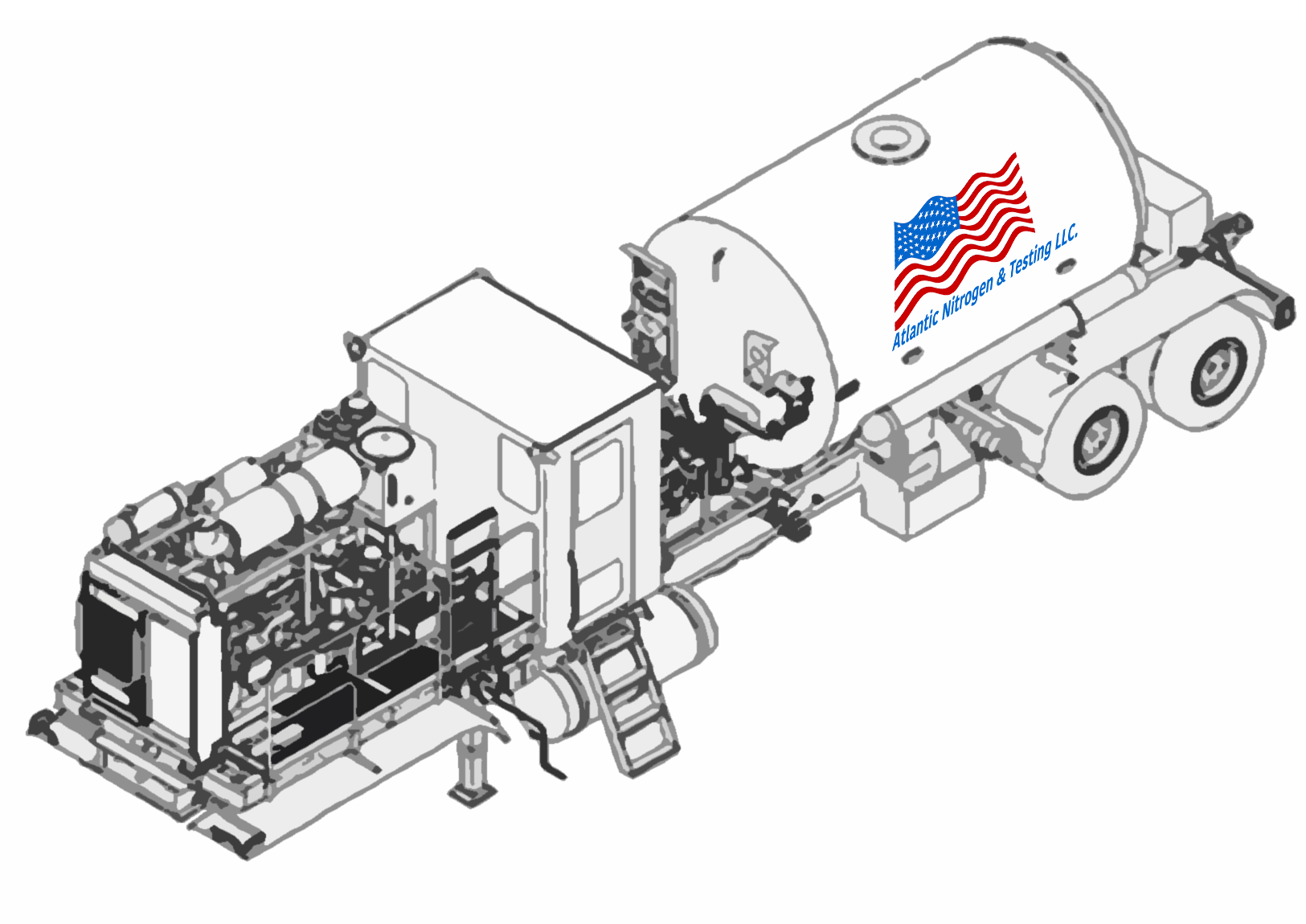

How Hydro Testing Works

Hydrostatic testing is a type of testing where a system is completely filled with water removing all of the air and pressurizing the vessel to a specified test pressure. The vessel is first filled with high flow pumps which can operate anywhere from 300-500 Gallons Per Minute (GPM) at 100-800 PSI of head pressure.

Once the system is full of water, high pressure pumps are used to bring the system to Maximum Allowable Operating Pressure (MAOP) or some other specified test pressure.